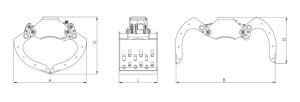

Clamshell Grapple

Features and Advantages

Robust Construction:

Built from high-strength steel, the Rima Clamshell Grapple is designed to withstand heavy-duty operations and harsh working environments. The solid structure ensures long-lasting durability and minimal maintenance requirements.

High Efficiency and Performance:

With a maximum pressure of 200 bar and a loading capacity of up to 250 kg, the grapple delivers strong clamping force and reliable performance for handling various bulk materials. It ensures smooth opening and closing actions, enabling fast loading and unloading operations.

Versatile Applications:

Suitable for excavators from 0.8 to 8 tons, the Rima Clamshell Grapple adapts easily to different job sites, including construction, landscaping, waste management, and agricultural material handling. Its compatibility across multiple excavator models enhances operational flexibility.

Compact Design and Easy Installation:

The lightweight design (50–100 kg depending on the model) allows easy attachment and removal, improving maneuverability and reducing stress on the excavator’s arm. It also contributes to fuel efficiency and overall operational safety.

Precision Handling:

The clamshell design enables precise material control, minimizing spillage and improving accuracy when handling fine or loose materials. This makes it ideal for tasks requiring careful placement and consistent productivity.

Low Maintenance and Long Service Life:

Equipped with high-quality components and wear-resistant materials, the Rima Clamshell Grapple requires minimal maintenance. The efficient hydraulic system reduces operating costs while maximizing uptime.

Multiple Models for Different Needs:

Available in two models—MR50 SG and MR125 SG—the series offers a choice between 150 kg and 250 kg maximum loading capacity, ensuring that customers can select the right configuration for their specific working requirements.

| Model | Max. Loading

(kg) |

Max. Pressure

(bar) |

Suitable Excavator

(ton) |

Weight

(kg) |

A

(mm) |

B

(mm) |

C

(mm) |

D

(mm) |

L

(mm) |

| MR50 SG | 150 | 200 | 0.8–5 | 50 | 626 | 894 | 492 | 390 | 330 |

| MR125 SG | 250 | 200 | 1.5–8 | 100 | 840 | 1200 | 660 | 523 | 450 |